Winning in today’s global marketplace requires more than just creating innovative product designs. To succeed, you must design products right the first time for optimal manufacturing, cost, quality, time, and functionality.

DFMPro Solutions

DFMPro is a powerful dfm software for creo platform, it is fully integrated inside PTC Creo Parametric. DFMPro enables design engineers to make informed design decisions and identify and address downstream manufacturability, assembly, quality and serviceability (DFx) related issues during early design stage.

DFMPro helps to capture and disseminate the industry best-practices and knowledge in form of DFx guidelines and brings in standardization across the organization.

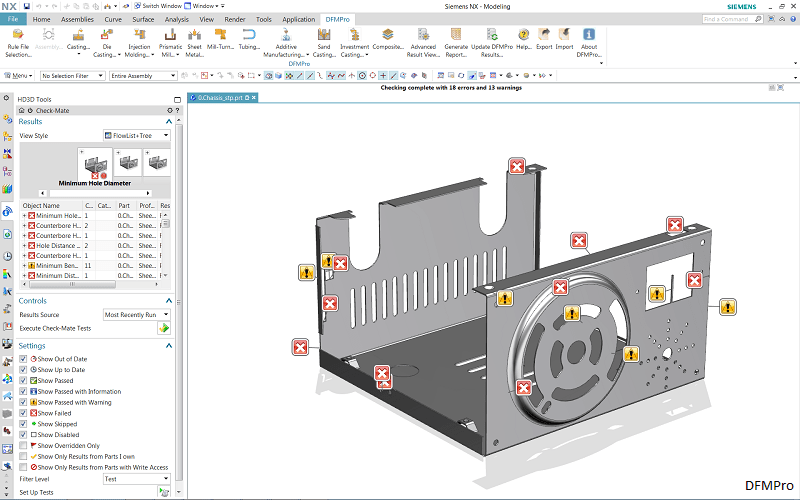

DFMPro for NX™, a best practice driven design for manufacturing software integrated within NX™, help design engineers to identify and evaluate their designs for downstream manufacturability, assembly, quality, serviceability, (DFx) related issues upfront and reduce unnecessary rework and engineering changes. It uses the existing, familiar and proven NX Check-Mate framework, and provides an HD3D interface for problem navigation and tagging. It facilitates out-of-the-box validation for manufacturing process like plastic injection molding, sheet metal fabrication, machining, casting, assembly and more.

DFMPro for SOLIDWORKS is a dfm software for SOLIDWORKS CAD platform that helps designers to check their designs for manufacturability and assembly within SOLIDWORKS interface and take corrective actions without multiple rounds of design iterations. The results can be visualized and interpreted conveniently in a 3D environment, making DFM validation process highly simple and cost effective.

- Easy to learn and use

- Seamlessly integrated within SOLIDWORKS

- Common manufacturability check related to machining, sheet-metal fabrication, additive manufacturing, assembly and injection molding

- Rule Manager to configure parameters and criticality of rules

- Provides reasons and suggests best practice related to manufacturability issues

Design For excellence or DFX is a systematic design approach that entails wide range of guidelines and standards focused on optimizing the product realization life-cycle. Design for Manufacturability and Design for Assembly (DFM & DFA), Design for Cost, Design for Serviceability, Design for Performance guidelines, and so on, ensure that issues related to manufacturing, cost, quality, assembly and serviceability are addressed right at the design stage. Geometric DFX is a Design for Manufacturing & Assembly Software. If these guidelines are not adhered during the design stage it can lead to engineering changes occurring at later stages of product life-cycle which are highly expensive and can cause product delays and cost over-runs.

- Reduce rework – improve productivity

- Shorten product development time

- Improves product designs and quality

- Captures expert knowledge and leanings

- Quick cost estimation to design engineers

Importance of DFMPro

One of the most important aspects of a DFM is avoiding mistakes that could lead to quality and productivity issues during manufacturing. These quality issues in turn translate into production costs and, even worse, into customer complaints and potential returns.

Apart from avoiding potential quality costs, one of the main goals of a DFM is to optimize the design of the product so it can be manufactured in the most cost effective way. Making some of these decisions early on can generate great savings in the final product and process.

Finally, DFM can help to estimate timings for your product manufacturing. Selecting the right production methods and supply chain can accelerate the time to production and avoid delays on critical components.

Industries

Aerospace & Defence

Automotive

Medical

Tool and Die Manufacturing

Industrial Manufacturing

High Tech

Get in touch

Transform your business to the next level.