CAE or Computer-Aided Engineering is a term used to describe the procedure of the entire product engineering process, from design and virtual testing with sophisticated analytical algorithms to the planning of manufacturing. Computer-aided engineering is standard in almost any industry that uses some sort of design software to develop products. CAE is the next step in not only designing a product but also supporting the engineering process, as it allows to perform tests and simulations of the product’s physical properties without needing a physical prototype. In the context of CAE, the most commonly used simulation analysis types include Finite Element Analysis, Computational Fluid Dynamics, Thermal Analysis, Multibody Dynamics, and Optimizations.

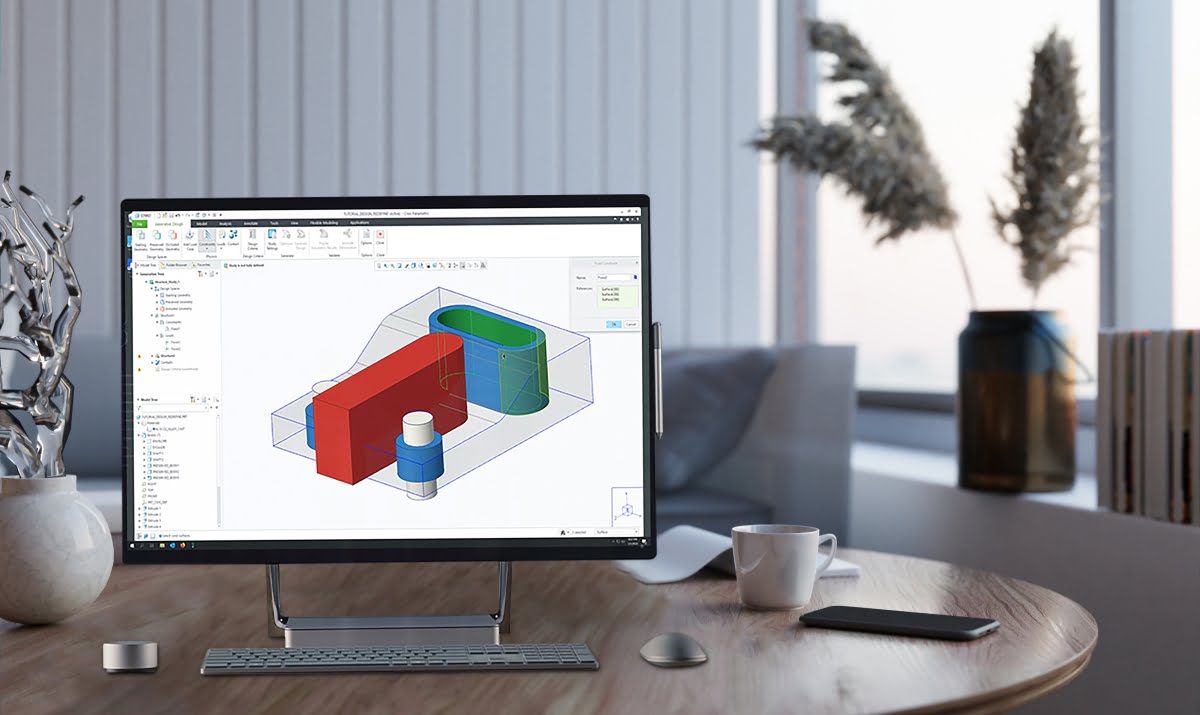

By leveraging the advantages of engineering simulation, especially when combined with the power and the speed of high-performance cloud computing, the cost and time of each design iteration cycle, as well as the overall development process, can be considerably reduced. The standard CAE workflow is to first generate an initial design and then simulate the CAD geometry. The simulation results are then evaluated and used to improve the design. This process is repeated until all the product’s requirements are met and virtually confirmed. In case of any weak spots or areas where the digital prototype’s performance doesn’t match the expectations, engineers and designers can improve the CAD model and check the effects of their change by testing the updated design in a new simulation. This process supports faster product development as there is no need for building physical prototypes in early development stages.

Simulating with CAE methods takes only a few hours at most, in comparison to days or probably weeks that building a physical prototype would require. Since it is inevitable to build a physical prototype of a product before beginning the serial production, simulation can help reduce the amount of those prototypes. When planning to integrate simulation techniques into the product development process, it is important to know about the environment (forces, temperatures, etc.) that the product will be exposed to. Knowing these conditions is crucial to properly set up a simulation. The predictive value of any simulation can only be the precision of the boundary conditions made. Up until now, besides predicting the environmental factors, engineering simulation was a complex endeavor by itself, mostly reserved for experienced engineers and simulation experts. Modern CAE simulation tools, such as SimScale, try to break these barriers, allowing inexperienced users without deep knowledge of the physical processes and solver characteristics to produce insightful simulation results.

Simulating complex geometries is difficult even with modern computers as it requires huge computing power for performance. Big companies with sophisticated IT infrastructure use their own servers to host and run simulations. However, the rise of HPC (High Performance Computing) in the cloud now also gives smaller companies, which usually can’t afford to buy and maintain the necessary hardware, the access to the same simulation tools and capabilities that previously were reserved only for a select few. This disruption in the market for simulation products makes it now possible for everyone to simulate the products they design.

Fields of application

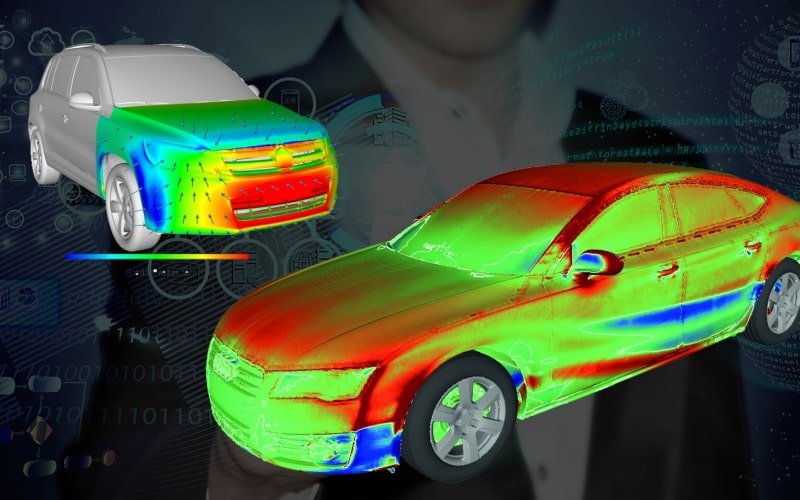

The main purpose of CAE is to test, predict and improve the robustness, performance, energy efficiency, and durability of components and assemblies, in the end creating better products and reducing the number of required physical prototypes and the time to market. Fluid flow, mass, and thermal transport, fluid-solid interaction, static or dynamic analysis, stress analysis on components and assemblies, conjugate heat transfer, conduction, convection, radiation, and more can be tested for a wide range of designs, using CAE software.

Computer-Aided Engineering (CAE) can be used in almost any industry that designs a product exposed to different environments. Industries using computer-aided engineering include but are not limited to automotive, aerospace, plant engineering, electronics, energy, consumer goods, and HVAC. The products range from extremely small parts to big and complex structures such as race cars, bridges, or even power plants.

Testing the structural integrity of a crane carrying a specific load to a rooftop, assessing the acoustic design of a concert hall, or the convective flow inside a light bulb; all are examples of applications where simulation can make a huge, sometimes life-saving difference.

Get in touch

Transform your business to the next level.